Working With Us

The Three Steps are:

Creative Discussion

1

Engineering Design

2

Production

3

Enabling Tomorrow’s Solutions for Better Living

Transformative Technology for Real-World Impact

At Mateligent iDEAS Inc., we are dedicated to developing solutions that not only advance technology but also improve quality of life. Our innovations in musculoskeletal measurement, fall reduction, and respiration measurement are just a few examples of how our technologies contribute to better living. By working with us, you are partnering with a company that prioritizes human-centric solutions, ensuring that our technology makes a meaningful impact on the world.

Why Mateligent iDEAS Inc. is the Right Partner for You

We are pioneers in electroactive polymer sensing technology, with unmatched knowledge and experience in the field.

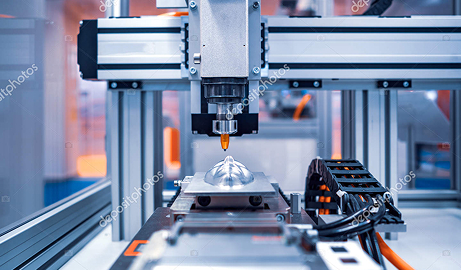

Our robust US-based manufacturing facilities ensure consistent quality and reliable delivery, supported by a stable and efficient supply chain.

Our technologies are not just concepts; they are fully developed and market-ready, providing you with solutions that are ready to deploy.

Our engineering expertise makes it an ideal partner for project conceptualization, sensor customization, electronics development, system integration, prototype development, and high-capacity production.

Our Expertise

From concept to high-volume production

Our engineering teams in the US and Germany collaborate closely with clients on projects, leveraging our expertise to quickly assess challenges and develop tailored solutions. From initial concept development to tooling, sample production, and beta testing, our process is designed to turn innovative concepts into tangible, market-ready products.

Our commitment to engineering excellence is complemented by our pending ISO 9001-certified facility in Bloomington, Minnesota, enabling us to scale production to meet high-volume demands while maintaining the highest standards of quality and efficiency.

Conceptualization & Design

Sensor Customization

Electronics Development

Device Integration

Prototype Design & Assembly

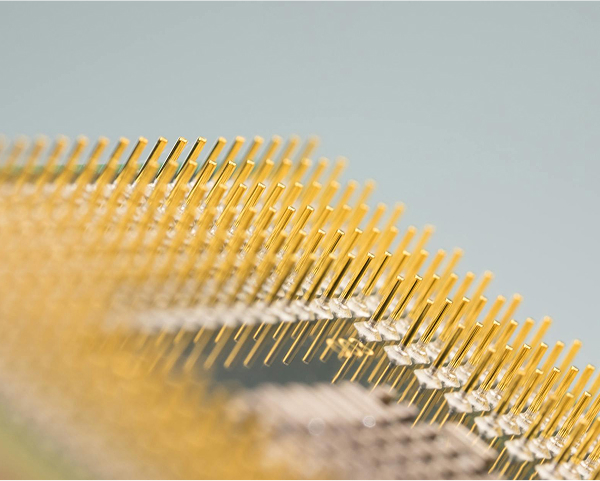

High-Volume Sensor Production

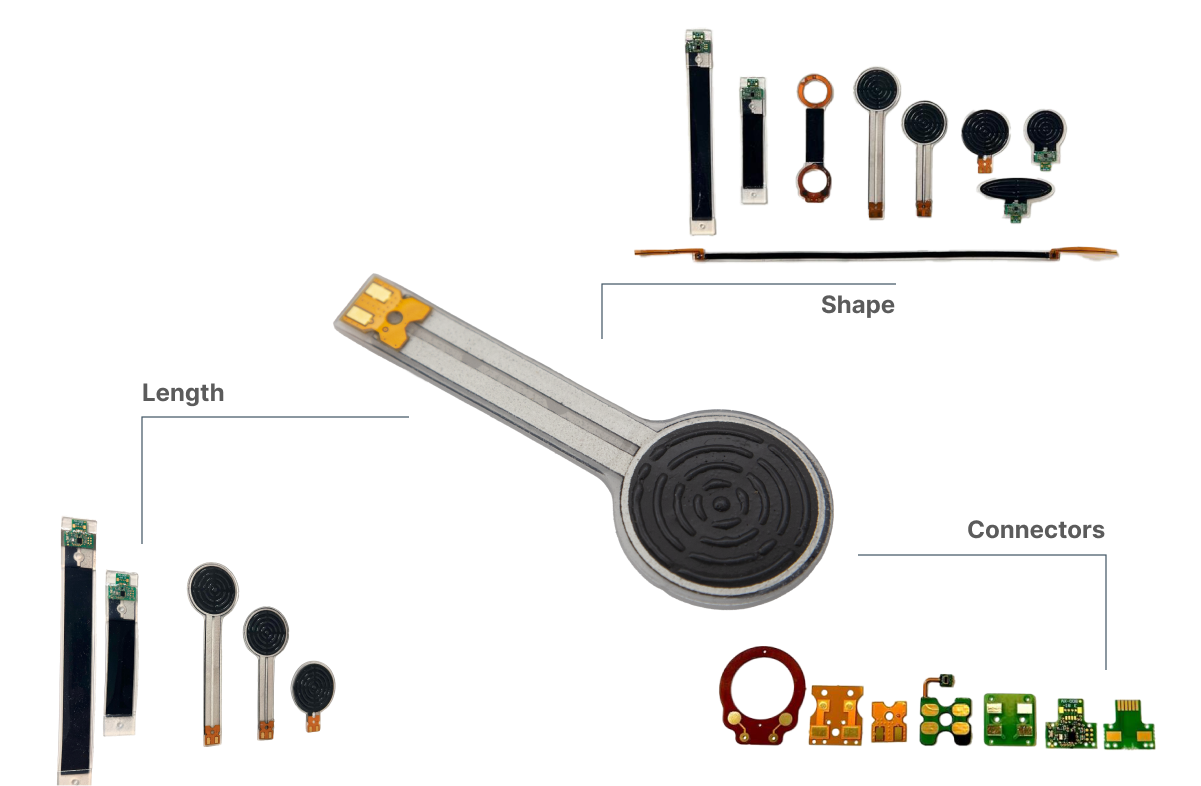

How Mateligent iDEAS Inc.’s Customization Works

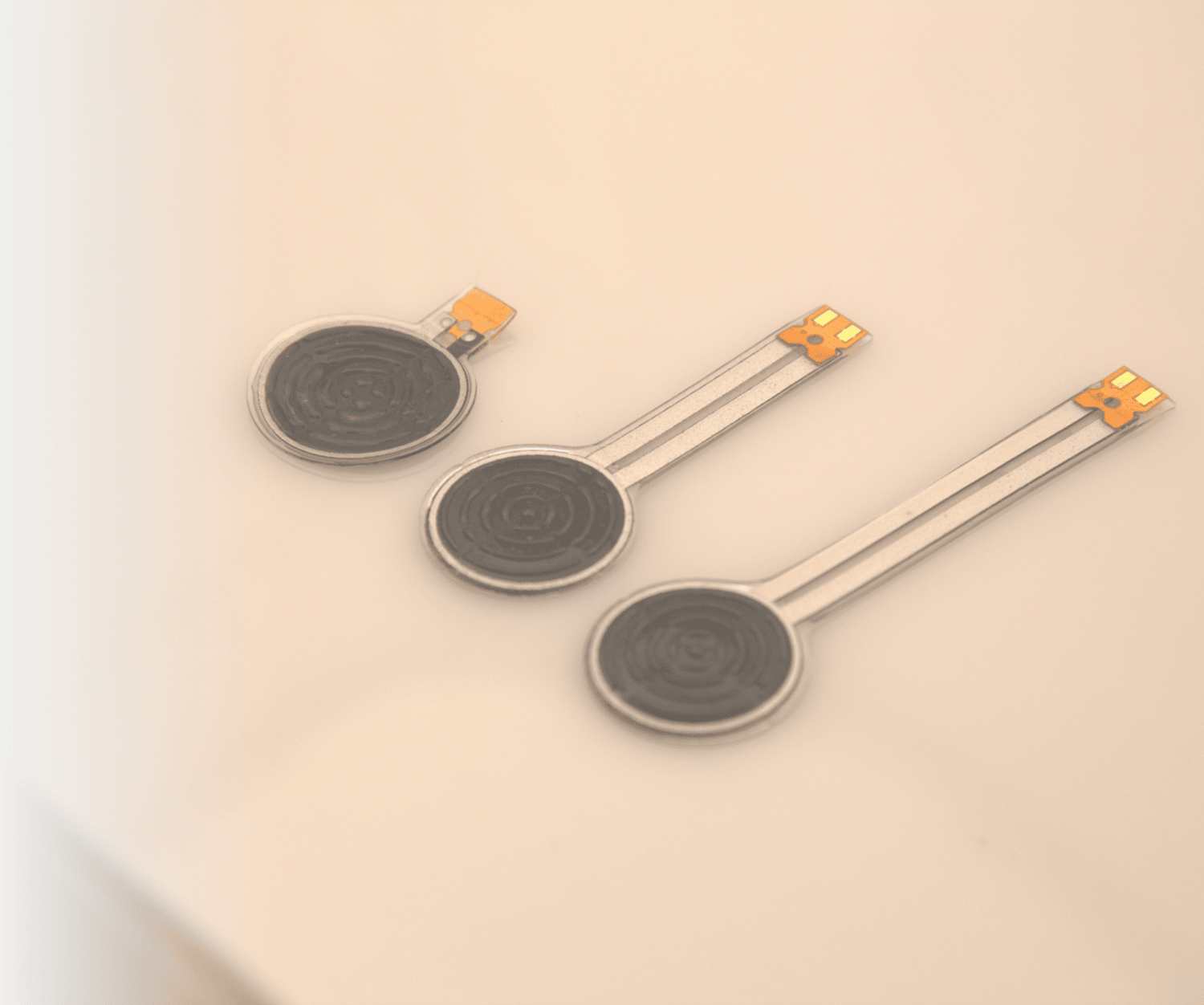

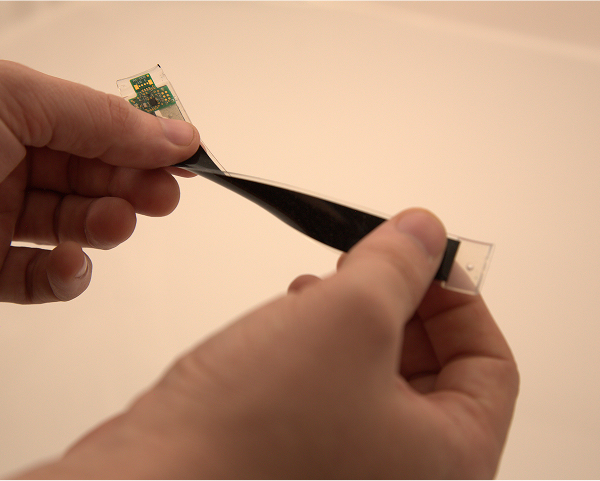

Customization is undertaken to ensure that sensors are optimized to meet the requirements of the use case. Customization most often involves the development of sensors with unique size and shape requirements. A more detailed level of customization involves manipulation of the physical properties of the sensors to optimize performance in more exacting applications. Electronics engineering is sometimes required according to project specifications.

One of the first questions we will ask is, “What do you want to measure?” From this reference point, the process begins. During one or two conversations, Mateligent will learn about your use case, assess feasibility, and generate a proposal. When assessing feasibility, we consider the concept from initial prototyping all the way to eventual high-volume production. Before proceeding with a project proposal, Mateligent first seeks to use existing sensors to meet requirements. This can alleviate the time and expense associated with the design and production of new tooling.

As part of developing a project proposal, Mateligent requires a high level of confidence that the sensors will be successful for the intended purpose, reducing technical risk, avoiding hidden project costs, and helping to keep the project on time. If we think an alternate sensing technology is more appropriate to meet the project requirements, we will recommend it.

Electronics are another dimension to consider in any project. Customers may prefer to supply their own electronics, use Mateligent’s, or develop new project-specific electronics. Mateligent is flexible in any situation.

From the start of a sensor customization project to the first production of several hundred units, a typical lead time is three months. This includes design and design revisions, tooling production and validation, and initial production. The initial production yields several hundred top-quality sensors that are ready for use. This is often sufficient volume to support all pre-launch development and beta testing.

Mateligent is often consulted for advice regarding the integration of the sensors into devices and also for production partners for the completed devices. Mateligent also offers prototype design and assembly capabilities as part of the customization process.

Customization extends beyond sensors to include the design, development, and fabrication of specialized arrays and testing devices used in product development, product testing, quality control, and production settings. These devices rely on Mateligent sensors that are assembled into low volumes of completed devices that are used by engineers and technicians as tools to do their work.